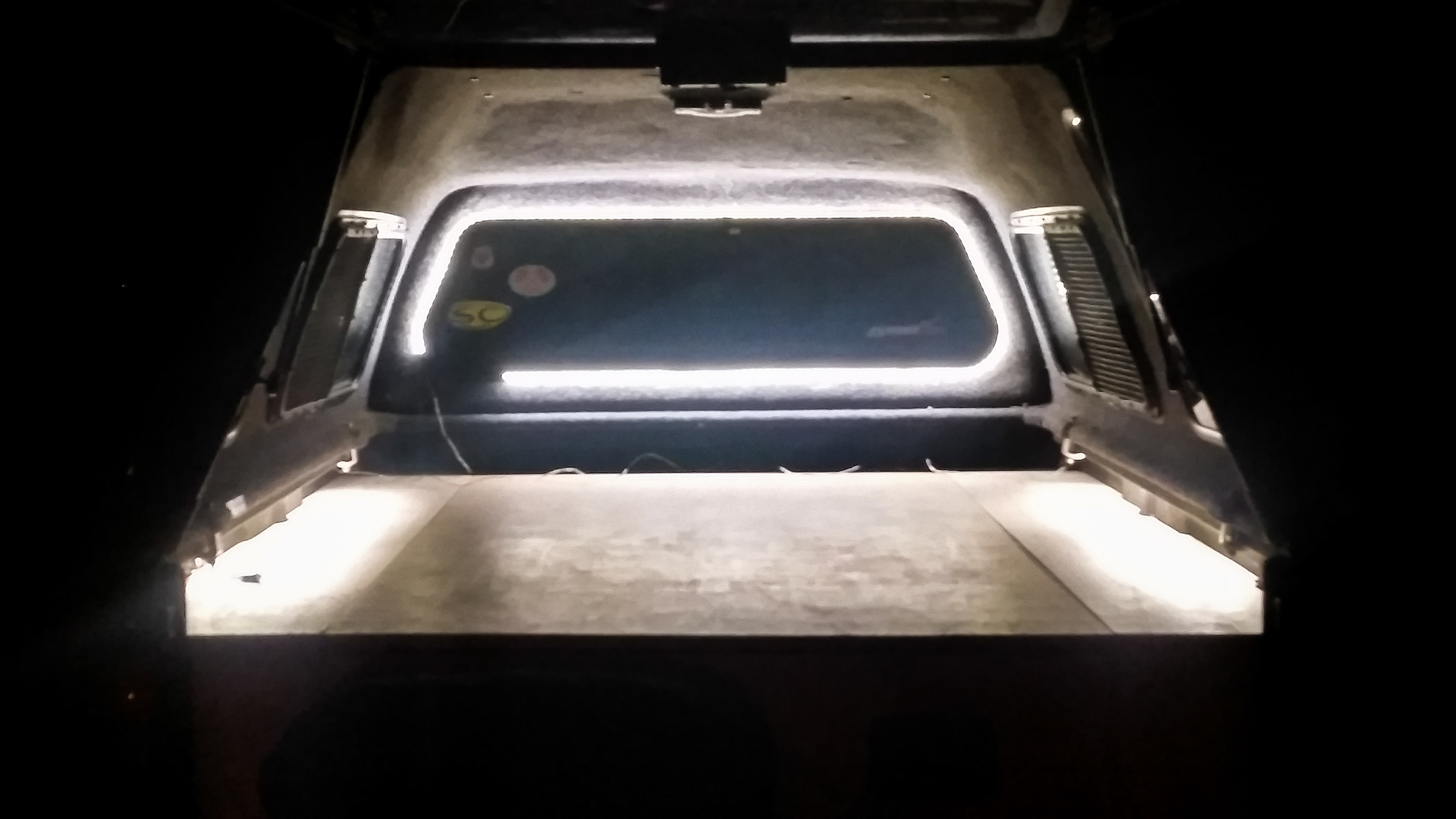

Below are some images and details from my drawer and platform build I did a few years back. I will likely do a write-up in the future on this.

No holes were drilled in the truck bed to secure this, it was all pressure fit and then bolted into place. I used zz608 bearings (commonly referred to as skateboard ball bearings). These slip over 5/8 inch bolts that I then tied into t-nuts. This allows for a system that I can install/remove repeatedly without much fanfare. With the system built modular, I can install or uninstall it in less than 20 minutes without the need for a second person. The slide rails utilized steel 1x1s that I epoxied in place and secured in place with 1/4" Allen key bolts that screwed into t-nuts. This ensured that the rails would be mechanically secured, but have additional support through the epoxy. Ultimately, this led to a drawer that can slide out 5.5 feet, and at full extension support 180 pounds hanging on the end (~1,000 ft/lbs of torque). I also used trampoline springs with paracord to ensure the drawer wouldn't overextend, but would also have a little dynamic give.